- The Industrial Solutions Experts

- info@fpt-ind.com

- 7277348589

The SPX Power Team portfolio features hydraulic pumps covering a wide variety of flow stage configurations and reservoir capacities, compact yet powerful jacks, cylinders (single and double acting) and valves (load-lowering, shut-off, pressure-reducing, sequence, metering, etc.). In addition, Power Team supplies nut splitters, in-line drives, spreaders, bridge lifts, shop presses, mobile floor cranes and torque wrenches. Through this comprehensive portfolio, Power Team attends to the needs of the construction, automotive assembly, mining, shipbuilding, manufacturing and industrial processing sectors.

Low Height Cylinders

Locking Collar Cylinders

Wide Range of General Purpose Cylinders

Single Acting and Double Acting

Well known and reliable PE55, PE172, and More Electric Pumps

Post-Tension and Stressing Specific Jacks

Bolt Tensioners and Accessories

Lightweight Aluminum Cylinders and Pumps

Hydraulic Torque Wrenches

Pullers and Nut-Splitters

Proudly Made in the USA

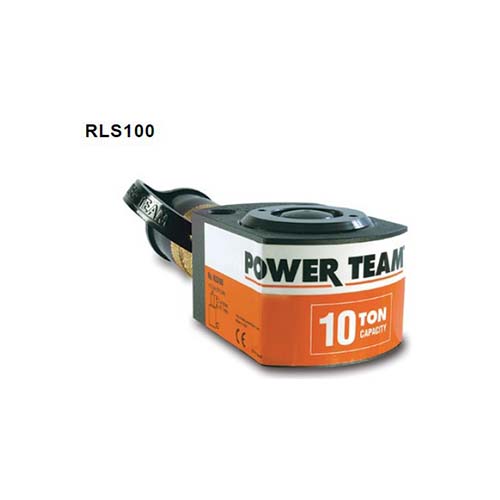

– Ideal for applications with height restrictions

– Low height starting at 1.63″ tall

– Solid steel cylinder body for durability

– Cylinder body, piston and gland nut are “Power-Tech” treated for corrosion and abrasion resistance

– RLS Standard domed piston rod (5-30 tons) or swivel cap (50-150 tons) minimize effects of off-center loading

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– RLS Unique heavy-duty spring provides fast piston return on all cylinders, except RLS50

– RSS Heavy-duty return spring (except for double-acting models) provides fast piston return & low collapsed height

– Grooved piston top keeps load from sliding

– RSS Cylinders can be “dead-ended” at full capacity

| Model Number | Capacity tons | Stroke inch | Oil cap. inch3 | Cyl. eff. area inch2 | Weight lbs |

| RLS Pad Cylinders | |||||

| RLS50 | 5 | 0.56 | 0.62 | 0.994 | 2.2 |

| RLS100 | 10 | 0.44 | 1 | 2.236 | 3.3 |

| RLS200 | 20 | 0.44 | 2 | 4.43 | 5.6 |

| RLS300 | 30 | 0.5 | 3.2 | 6.492 | 8.6 |

| RLS500S | 50 | 0.63 | 6 | 9.621 | 14 |

| RLS750S | 75 | 0.63 | 9.9 | 15.904 | 23.3 |

| RLS1000S | 100 | 0.63 | 12.3 | 19.635 | 30 |

| RLS1500S | 150 | 0.56 | 17.2 | 30.68 | 52 |

| RSS Shorty Cylinders | |||||

| RSS101 | 10 | 1.5 | 3.4 | 2.24 | 6 |

| RSS202 | 20 | 1.75 | 7.7 | 4.43 | 9.9 |

| RSS302 | 30 | 2.44 | 15.8 | 6.49 | 14.7 |

| RSS502 | 50 | 2.38 | 22.8 | 9.62 | 23.2 |

| RSS1002 | 100 | 2.25 | 44.2 | 19.63 | 47.3 |

| RSS2503 | 250 | 3 | 150.6 | 50.22 | 220 |

| RSS Shorty Special Double Acting Model | |||||

| RSS1002D | 100 | 1.5 | 29.4 | 19.63 | 54.6 |

– Very wide range of closed heights and strokes

– Aluminum bronze bearing reduces wear caused by off-center loads

– Solid steel cylinder body for durability

– Maximum sized springs speed piston return and increase spring life

– Collar threads are standard on all C-Series models, simplifying fixturing applications

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– Base mounting holes standard on 5 through 55 ton cylinders and optional on 75 and 100 ton cylinders

– Chrome plated piston rod resists wear and corrosion

– Some models available as Aluminum Lightweight Cylinders.

| Model | Tons at 10,000 (tons) |

Stroke (in.) |

Oil Cap. (cu. in.) |

Cylinder Effective Area (sq. in) |

Prod. Wt. (lbs.) |

| C51C | 4.97 | 1 | 1.1 | 0.994 | 2.25 |

| C53C | 4.97 | 3.25 | 3.2 | 0.994 | 3.26 |

| C55C | 4.97 | 5.25 | 5.2 | 0.994 | 4 |

| C57C | 4.97 | 7.25 | 7.2 | 0.994 | 5 |

| C59C | 4.97 | 9.25 | 9.2 | 0.994 | 5.8 |

| C101C | 11.2 | 1 | 2.2 | 2.236 | 4 |

| C102C | 11.2 | 2.13 | 4.8 | 2.236 | 5 |

| C104C | 11.2 | 4.13 | 9.2 | 2.236 | 6.7 |

| C106C | 11.2 | 6.13 | 13.7 | 2.236 | 9.4 |

| C108C | 11.2 | 8.13 | 19.9 | 2.236 | 11 |

| C1010C | 11.2 | 10.13 | 22.6 | 2.236 | 13 |

| C1012C | 11.2 | 12.13 | 27.1 | 2.236 | 14.6 |

| C1014C | 11.2 | 14.13 | 31.6 | 2.236 | 16.2 |

| C1016C | 11.2 | 16 | 36.1 | 2.236 | 18.5 |

| C151C | 15.7 | 1 | 3.1 | 3.142 | 7.5 |

| C152C | 15.7 | 2.13 | 6.7 | 3.142 | 8.9 |

| C154C | 15.7 | 4.13 | 12.9 | 3.142 | 11.5 |

| C156C | 15.7 | 6.13 | 19.2 | 3.142 | 15.3 |

| C158C | 15.7 | 8.13 | 25.5 | 3.142 | 17.9 |

| C1510C | 15.7 | 10.13 | 31.8 | 3.142 | 20.7 |

| C1512C | 15.7 | 12.13 | 38.1 | 3.142 | 23.2 |

| C1514C | 15.7 | 14.13 | 44.4 | 3.142 | 26 |

| C1516C | 15.7 | 16 | 50.3 | 3.142 | 28.2 |

| C251C | 25.8 | 1 | 5.1 | 5.15 | 11.9 |

| C252C | 25.8 | 2 | 10.3 | 5.15 | 13.9 |

| C254C | 25.8 | 4 | 20.6 | 5.15 | 17.6 |

| C256C | 25.8 | 6.25 | 32.2 | 5.15 | 21.7 |

| C258C | 25.8 | 8.25 | 42.5 | 5.15 | 25.6 |

| C2510C | 25.8 | 10.25 | 52.8 | 5.15 | 29.3 |

| C2512C | 25.8 | 12.25 | 63.2 | 5.15 | 33.1 |

| C2514C | 25.8 | 14.25 | 73.5 | 5.15 | 36.8 |

| C308C | 32.5 | 8.25 | 53.55 | 6.46 | 36.5 |

| C552C | 55.2 | 2 | 22.1 | 11.04 | 32.5 |

| C554C | 55.2 | 4.25 | 46.9 | 11.04 | 41.3 |

| C556C | 55.2 | 6.25 | 69 | 11.04 | 51 |

| C5510C | 55.2 | 10.25 | 113.2 | 11.04 | 67 |

| C5513C | 55.2 | 13.25 | 146.3 | 11.04 | 78 |

| C756C | 79.5 | 6.13 | 97.4 | 15.9 | 73.5 |

| C7513C | 79.5 | 13.13 | 208.7 | 15.9 | 109.5 |

| C1002C | 103.1 | 2 | 41.2 | 20.62 | 63 |

| C1006C | 103.1 | 6.63 | 137 | 20.62 | 91 |

| C10010C | 103.1 | 10.25 | 211.5 | 20.62 | 113 |

– Ideal for cable pulling and tensioning applications

– Cylinder body, piston and gland nut “Power-Tech” treated for corrosion and abrasion resistance

– Most models feature threaded collar, excludes the RH203 and RHA306 models

– Aluminum cylinder body and piston are featured on the RHA306 cylinder

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– Plated piston rod resists wear and superior packings provide high cycle life without leakage

– RH Double Acting Built-in safety feature prevents over-pressurization

– Aluminum cylinder body and piston are featured on the RHA604D cylinder

| Model Number | Capacity tons | Stroke inch | Oil cap. inch3 | Cyl. eff. area inch2 | Hole Diameter Inches | Weight lbs |

| RH Hollow Single Acting Spring Return | ||||||

| RH102 | 11 | 2.5 | 5.52 | 2.21 | 0.77 | 9 |

| RH108 | 11 | 8 | 17.68 | 2.21 | 0.77 | 18.7 |

| RH120** | 13.8 | 0.31 | 0.87 | 2.76 | 0.8 | 3 |

| RH121 | 13.8 | 1.63 | 4.49 | 2.76 | 0.8 | 6.6 |

| RH121T* | 13.8 | 1.63 | 4.49 | 2.76 | 0.81 | 6.6 |

| RH123 | 13.8 | 3 | 8.29 | 2.76 | 0.81 | 8.9 |

| RH202 | 23.6 | 2 | 9.45 | 4.72 | 1.08 | 16.1 |

| RH203 | 19.6 | 3 | 11.76 | 3.92 | 1.05 | 20 |

| RH206 | 23.6 | 6 | 28.35 | 4.72 | 1.08 | 30.2 |

| RH302 | 31.7 | 2.5 | 15.85 | 6.34 | 1.3 | 25.6 |

| RHA306 | 31.7 | 5.88 | 38.1 | 6.34 | 1.28 | 21.9 |

| RH306 | 31.7 | 6 | 38.1 | 6.34 | 1.28 | 39 |

| RH503 | 54.3 | 3 | 32.58 | 10.86 | 1.67 | 46.6 |

| RH603* | 61.6 | 3 | 37 | 12.31 | 2.13 | 60 |

| RH606* | 61.6 | 6 | 73.86 | 12.31 | 2.13 | 78 |

| RH1003* | 103.1 | 3 | 61.8 | 20.62 | 3.13 | 115 |

| RT Hollow Series | ||||||

| RT172 | 17.5 | 2 | 7.06 | 3.53 | 1.03 | 14.6 |

| RT302 | 30 | 2.5 | 15.7 | 6.28 | 1.3 | 28.2 |

| RT503 | 50 | 3 | 29.4 | 9.81 | 1.67 | 56 |

| RT Hollow Double Acting Series | ||||||

| RT1004 | 100 | 4.88 | 96.5 | 19.24 | 2.56 | 160 |

| Model Number | Push Tons | Pull Tons | Stroke in. | Oil cap. inch3 | Hole Diameter Inch | Weight lbs. |

| RH Double Acting Hollow Series | ||||||

| RH303 | 30 | 15 | 3 | 17.6 | 1.28 | 29.8 |

| RH306D | 30 | 15 | 6 | 35.34 | 1.27 | 45 |

| RH3010 | 30 | 20 | 10.13 | 66 | 1.31 | 61 |

| RHA604D | 60 | 25 | 4 | 49.2 | 2.13 | 35.6 |

| RH605* | 60 | 25 | 5 | 61.55 | 2.13 | 73 |

| RH6010* | 60 | 40 | 10.13 | 133 | 2.13 | 120 |

| RH1001 | 100 | 45 | 1.5 | 32.1 | 3.14 | 85 |

| RH1006* | 100 | 50 | 6 | 120.2 | 2.06 | 95 |

| RH10010* | 100 | 45 | 10.13 | 216.6 | 3.14 | 240 |

| RH1505* | 150 | 70 | 5 | 150.9 | 2.56 | 148 |

| RH1508* | 150 | 75 | 8 | 239.6 | 3.16 | 227 |

| RH2008* | 200 | 75 | 8 | 323.6 | 4.06 | 311 |

– Lightweight and easy to transport

– Approximately half the weight of comparable steel counterparts

– Hard coated aluminum piston rod and cylinder bore resist wear and corrosion

– Aluminum body resists sparking in explosive environments

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– RA_L Locking Collar Supports lifted load for extended periods f time with hydraulic pressure released

– RA_L Load Return

– Wide Range of Steel General Purpose Cylinders

– Wide Range of Steel Locking Collar Available

| Model | Tons at 10,000 (tons) |

Stroke (in.) |

Oil Cap. (cu. in.) |

Cylinder Effective Area (sq. in) |

Prod. Wt. (lbs.) |

| RA Spring Return Single Acting Aluminum Series | |||||

| RA202 | 22.15 | 2.13 | 9.41 | 4.43 | 7.7 |

| RA204 | 22.15 | 4.13 | 18.27 | 4.43 | 9.3 |

| RA206 | 22.15 | 6.13 | 27.13 | 4.43 | 11.3 |

| RA302 | 32.45 | 2.13 | 13.79 | 6.49 | 11.1 |

| RA304 | 32.45 | 4.13 | 26.77 | 6.49 | 13.1 |

| RA306 | 32.45 | 6.13 | 39.75 | 6.49 | 15.1 |

| RA552 | 55.2 | 2.13 | 23.5 | 11.04 | 16.2 |

| RA554 | 55.2 | 4.13 | 45.5 | 11.04 | 19.6 |

| RA556* | 55.2 | 6.13 | 67.6 | 11.04 | 24 |

| RA5510* | 55.2 | 10 | 110.4 | 11.04 | 31.8 |

| RA1002 | 103.1 | 2.13 | 43.8 | 20.62 | 33.4 |

| RA1006* | 103.1 | 6.25 | 129 | 20.62 | 49.9 |

| RA10010* | 103.1 | 10.25 | 21 | 20.62 | 67 |

| RA_L Aluminum Locking Collar Load Return Series | |||||

| RA556L | 55.2 | 6.13 | 67.6 | 11.04 | 29.6 |

| RA1006L | 103.1 | 6.25 | 129 | 20.62 | 64 |

– Supports lifted load for extended periods of time with hydraulic pressure released

– Visible indicator band alerts when stroke limit is reached. Overflow port (“weep hole”) stroke limiter prevents piston from being overextended

– All cylinders feature coated pistons to resist corrosion and abrasion

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– RGP and ZCL Include Patented 5 degree deep swivel cap concentrates loads to minimize offset conditions

– RGP Compact design is ideal for confined areas

– Load Return

– Aluminum Lightweight Options Available

| Model | Tons at 10,000 (tons) |

Stroke (in.) |

Oil Cap. (cu. in.) |

Cylinder Effective Area (sq. in) |

Prod. Wt. (lbs.) |

| RGP Low Height Pancake Load Return Series | |||||

| RGP672 | 66.8 | 1.75 | 23.39 | 13.36 | 33.5 |

| RGP1102 | 113.4 | 1.75 | 39.71 | 22.69 | 52.3 |

| RGP1802 | 178.9 | 1.75 | 62.62 | 35.78 | 97.2 |

| RGP2202 | 220.9 | 1.75 | 77.31 | 44.18 | 127.2 |

| RGP2802 | 283.7 | 1.75 | 99.3 | 56.74 | 155.2 |

| RGP4302 | 432.9 | 1.75 | 151.53 | 86.59 | 282.5 |

| RGP5652 | 565.5 | 1.75 | 197.91 | 113.09 | 398.7 |

| R_L Load Return Series | |||||

| R552L | 55.2 | 2 | 22.1 | 11.04 | 33.7 |

| R556L | 55.2 | 6 | 66.3 | 11.04 | 58 |

| R5510L | 55.2 | 10 | 110.4 | 11.04 | 80 |

| R1002L | 103 | 2 | 41.3 | 20.63 | 66 |

| R1006L | 103 | 6 | 123.8 | 20.63 | 103 |

| R10010L | 103 | 10 | 206.3 | 20.63 | 142 |

| R1502L | 153.4 | 2 | 61.4 | 30.68 | 117 |

| R1506L | 153.4 | 6 | 184.1 | 30.68 | 177 |

| R15010L | 153.4 | 10 | 306.8 | 30.68 | 235 |

| R2002L | 206.4 | 2 | 82.6 | 41.28 | 183 |

| R2006L | 206.4 | 6 | 247.7 | 41.28 | 259 |

| R2008L | 206.4 | 8 | 330.3 | 41.28 | 265 |

| R2802L | 283.7 | 2 | 113.5 | 56.74 | 261 |

| R2806L | 283.7 | 6 | 340.4 | 56.74 | 359 |

| R28010L | 283.7 | 10 | 567.4 | 56.74 | 459 |

| R3552L | 354.4 | 2 | 141.8 | 70.88 | 381 |

| R3556L | 354.4 | 6 | 425.3 | 70.88 | 512 |

| R4302L | 433 | 2 | 173.2 | 86.59 | 556 |

| R4306L | 433 | 6 | 519.5 | 86.59 | 725 |

| R43010L | 433 | 10 | 865.9 | 86.59 | 894 |

| R5652L | 565.5 | 2 | 226.2 | 113.1 | 811 |

| R5656L | 565.5 | 6 | 678.6 | 113.1 | 1031 |

| R56510L | 565.5 | 10 | 1131 | 113.1 | 1251 |

| ZCL Load Return Very High Tonnage | |||||

| ZCL500-2 | 550 | 2 | 222.9 | 113.2 | 875 |

| ZCL500-4 | 550 | 4 | 445.8 | 113.2 | 985 |

| ZCL500-6 | 550 | 6 | 668.8 | 113.2 | 1093 |

| ZCL500-8 | 550 | 8 | 891.7 | 113.2 | 1206 |

| ZCL500-10 | 550 | 10 | 1114.6 | 113.2 | 1316 |

| ZCL500-12 | 550 | 12 | 1337.6 | 113.2 | 1426 |

| ZCL600-2 | 660 | 2 | 261 | 132.6 | 1116 |

| ZCL600-4 | 660 | 4 | 521.9 | 132.6 | 1199 |

| ZCL600-6 | 660 | 6 | 782.9 | 132.6 | 1327 |

| ZCL600-8 | 660 | 8 | 1043.9 | 132.6 | 1457 |

| ZCL600-10 | 660 | 10 | 1304.9 | 132.6 | 1585 |

| ZCL600-12 | 660 | 12 | 1565.8 | 132.6 | 1713 |

| ZCL800-2 | 880 | 2 | 358.9 | 182.3 | 1717 |

| ZCL800-4 | 880 | 4 | 717.8 | 182.3 | 1893 |

| ZCL800-6 | 880 | 6 | 1076.7 | 182.3 | 2072 |

| ZCL800-8 | 880 | 8 | 1435.6 | 182.3 | 2249 |

| ZCL800-10 | 880 | 10 | 1794.5 | 182.3 | 2425 |

| ZCL800-12 | 880 | 12 | 2153.5 | 182.3 | 2601 |

| ZCL1000-2 | 1100 | 2 | 447.2 | 227.2 | 2313 |

| ZCL1000-4 | 1100 | 4 | 894.4 | 227.2 | 2524 |

| ZCL1000-6 | 1100 | 6 | 1341.7 | 227.2 | 2736 |

| ZCL1000-8 | 1100 | 8 | 1788.9 | 227.2 | 2950 |

| ZCL1000-10 | 1100 | 10 | 2236.2 | 227.2 | 3161 |

| ZCL1000-12 | 1100 | 12 | 2683.3 | 227.2 | 3373 |

The P series manual two-speed pumps are used with singleacting cylinders. The two-speed feature provides high oil volume for fast cylinder piston approach to the work, then the pump automatically shifts to the high pressure stage. This reduces the number of pump handle strokes required.

PE55 and PED25 Series – Equipped with a 1-1/8 hp, single-phase universal motor, have a 90-95 dBA noise level. Offer the best weight to performance ratio of any Power Team electric/hydraulic pump. CSA rated for intermittent duty. The PED25 versions are “dual flow” pumps which deliver the same low and high pressures to both valves, and have a noise level of 80-85 dBA. They have a 1-1/2 hp induction motor.

PB102 Series of portable pumps powered by Milwaukee M18 batteries: Quiet, smooth-running, serviceable brushed 18VDC motor, Two-stage, high-pressure hydraulic pump offers quick tool advancement in the first stage, and are Extremely compact, lightweight with an ergonomic handle grip and transport strap to ease portability.

– P Series Aluminum Lightweight Single and Double Acting Hand Pumps

– Steel Single and Double Acting Hand Pumps

– PB Series Battery Pump Using Milwaukee M18 Batteries

– PA6 Series Pneumatic Foot Pumps

– PE172 Electric Pump for General Purpose Cylinders

– Well Known and Reliable PE55 Pumps for Single and Double Acting Cylinders and Torque Wrench Setups

– Synchronous Lifting MCS-PE554-8 Pumps

– Tensioner Pumps Available in Electric, Air, and Manual on Pa ge 91 of Bolting Catalog

– Single and Double Acting, load return hydraulic cylinders up to 1650 TONS

– Floating piston design resists side loading conditions

– RGG and RDG “Power-Tech” nitro-carburization surface treatment inhibits corrosion and provides exceptional durability

– Maximum sized springs speed piston return and increase spring life

– Safety relief valves to prevent over-pressurization

– Working Pressure of 10,000 PSI

– Complies with ANSI / ASME B30.1 Safety Standards

– RD Aluminum bronze overlay bearings provide long life

– RD Rod and collar threads are designed to withstand full tonnage

– R Series Visible indicator band alerts when stroke limit is reached. Overflow port (weep hole) stroke limiter prevents piston from being overextended

– R Series Plated piston rod increases corrosion resistance and gives superior bearing support

| Double Acting | Single Acting | ||||||||||||

| Model Number | Push Tons | Pull Tons | Stroke in. | Oil cap. inch3 | Cyl. eff. area inch2 | Weight lbs. | Model Number | Capacity tons | Stroke inch | Oil cap. inch3 | Cyl. eff. area inch2 | Weight lbs | |

| RD General Series | RGG Load Return Series | ||||||||||||

| RD106 | 10 | 4 | 6.25 | 13.9 | 2.23 | 22 | RGG552 | 55.2 | 2 | 22.09 | 11.04 | 34.6 | |

| RD1010 | 10 | 4 | 10 | 22.3 | 2.23 | 28 | RGG554 | 55.2 | 4 | 44.18 | 11.04 | 43.6 | |

| RD256 | 25 | 8 | 6.25 | 32.2 | 5.15 | 39.8 | RGG556 | 55.2 | 6 | 66.27 | 11.04 | 52.5 | |

| RD2514 | 25 | 8 | 14.25 | 73.5 | 5.15 | 65 | RGG558 | 55.2 | 8 | 88.35 | 11.04 | 61.5 | |

| RD556 | 55 | 28 | 6.25 | 69 | 11.04 | 61.4 | RGG5510 | 55.2 | 10 | 110.44 | 11.04 | 70.5 | |

| RD5513 | 55 | 28 | 13.13 | 144.9 | 11.04 | 90 | RGG5512 | 55.2 | 12 | 132.53 | 11.04 | 79.4 | |

| RD5518 | 55 | 28 | 18.13 | 200 | 11.04 | 142 | RGG5513 | 55.2 | 13 | 143.58 | 11.04 | 83.9 | |

| RD8013 | 80 | 44 | 13.13 | 208.6 | 15.9 | 118 | RGG5514 | 55.2 | 14 | 154.62 | 11.04 | 88.4 | |

| RD1006 | 100 | 44 | 6.63 | 136.7 | 20.63 | 126 | RGG752 | 75.2 | 2 | 30.07 | 15.03 | 45 | |

| RD10013 | 100 | 44 | 13.13 | 270.7 | 20.63 | 181 | RGG754 | 75.2 | 4 | 60.13 | 15.03 | 55.7 | |

| RD10020 | 100 | 44 | 20.13 | 415.2 | 20.63 | 260 | RGG756 | 75.2 | 6 | 90.2 | 15.03 | 66.4 | |

| RD1506 | 150 | 73 | 6.63 | 203.3 | 30.68 | 188 | RGG758 | 75.2 | 8 | 120.26 | 15.03 | 77.1 | |

| RD15013 | 150 | 73 | 13.13 | 402.7 | 30.68 | 272 | RGG7510 | 75.2 | 10 | 150.33 | 15.03 | 87.9 | |

| RD15018 | 150 | 73 | 18.13 | 556.8 | 30.68 | 376 | RGG7512 | 75.2 | 12 | 180.39 | 15.03 | 98.6 | |

| RD2006 | 200 | 113 | 6.63 | 273.5 | 41.28 | 262 | RGG7513 | 75.2 | 13 | 195.42 | 15.03 | 104 | |

| RD20013 | 200 | 113 | 13.13 | 541.8 | 41.28 | 356 | RGG7514 | 75.2 | 14 | 210.46 | 15.03 | 109.3 | |

| RD20018 | 200 | 113 | 18.13 | 748.2 | 41.28 | 442 | RGG1002 | 103.1 | 2 | 41.26 | 20.63 | 59.2 | |

| RD3006 | 300 | 147 | 6 | 361 | 60.13 | 380 | RGG1004 | 103.1 | 4 | 82.51 | 20.63 | 72.7 | |

| RD30013 | 300 | 147 | 13 | 782 | 60.13 | 654 | RGG1006 | 103.1 | 6 | 123.77 | 20.63 | 86.2 | |

| RD4006 | 400 | 186 | 6 | 471 | 78.54 | 585 | RGG1008 | 103.1 | 8 | 165.03 | 20.63 | 99.8 | |

| RD40013 | 400 | 186 | 13 | 1021 | 78.54 | 770 | RGG10010 | 103.1 | 10 | 206.28 | 20.63 | 113.3 | |

| RD5006 | 500 | 245 | 6 | 596 | 99.4 | 819 | RGG10012 | 103.1 | 12 | 247.54 | 20.63 | 126.8 | |

| RD50013 | 500 | 245 | 13 | 1292 | 99.4 | 1092 | RGG10013 | 103.1 | 13 | 268.17 | 20.63 | 133.6 | |

| RDG High Tonnage Series | RGG10014 | 103.1 | 14 | 288.8 | 20.63 | 140.3 | |||||||

| RGG552 | 55.2 | LR | 2 | 22.09 | 11.04 | 34.6 | RGG1502 | 153.4 | 2 | 61.36 | 30.68 | 91.3 | |

| RGG554 | 55.2 | LR | 4 | 44.18 | 11.04 | 43.6 | RGG1504 | 153.4 | 4 | 122.71 | 30.68 | 109.6 | |

| RGG556 | 55.2 | LR | 6 | 66.27 | 11.04 | 52.5 | RGG1506 | 153.4 | 6 | 184.07 | 30.68 | 128 | |

| RGG558 | 55.2 | LR | 8 | 88.35 | 11.04 | 61.5 | RGG1508 | 153.4 | 8 | 245.43 | 30.68 | 146.4 | |

| RGG5510 | 55.2 | LR | 10 | 110.44 | 11.04 | 70.5 | RGG15010 | 153.4 | 10 | 306.79 | 30.68 | 164.7 | |

| RGG5512 | 55.2 | LR | 12 | 132.53 | 11.04 | 79.4 | RGG15012 | 153.4 | 12 | 368.14 | 30.68 | 183.1 | |

| RGG5513 | 55.2 | LR | 13 | 143.58 | 11.04 | 83.9 | RGG15013 | 153.4 | 13 | 398.82 | 30.68 | 192.3 | |

| RGG5514 | 55.2 | LR | 14 | 154.62 | 11.04 | 88.4 | RGG15014 | 153.4 | 14 | 429.5 | 30.68 | 201.4 | |

| RGG752 | 75.2 | LR | 2 | 30.07 | 15.03 | 45 | RGG2002 | 206.4 | 2 | 82.56 | 41.28 | 136.1 | |

| RGG754 | 75.2 | LR | 4 | 60.13 | 15.03 | 55.7 | RGG2004 | 206.4 | 4 | 165.13 | 41.28 | 161 | |

| RGG756 | 75.2 | LR | 6 | 90.2 | 15.03 | 66.4 | RGG2006 | 206.4 | 6 | 247.69 | 41.28 | 185.9 | |

| RGG758 | 75.2 | LR | 8 | 120.26 | 15.03 | 77.1 | RGG2008 | 206.4 | 8 | 330.25 | 41.28 | 210.9 | |

| RGG7510 | 75.2 | LR | 10 | 150.33 | 15.03 | 87.9 | RGG20010 | 206.4 | 10 | 412.81 | 41.28 | 235.8 | |

| RGG7512 | 75.2 | LR | 12 | 180.39 | 15.03 | 98.6 | RGG20012 | 206.4 | 12 | 495.38 | 41.28 | 260.7 | |

| RGG7513 | 75.2 | LR | 13 | 195.42 | 15.03 | 104 | RGG20013 | 206.4 | 13 | 536.66 | 41.28 | 273.2 | |

| RGG7514 | 75.2 | LR | 14 | 210.46 | 15.03 | 109.3 | RGG20014 | 206.4 | 14 | 577.94 | 41.28 | 285.6 | |

| RGG1002 | 103.1 | LR | 2 | 41.26 | 20.63 | 59.2 | RGG2502 | 251.3 | 2 | 100.53 | 50.26 | 202.4 | |

| RGG1004 | 103.1 | LR | 4 | 82.51 | 20.63 | 72.7 | RGG2504 | 251.3 | 4 | 201.06 | 50.26 | 235.4 | |

| RGG1006 | 103.1 | LR | 6 | 123.77 | 20.63 | 86.2 | RGG2506 | 251.3 | 6 | 301.58 | 50.26 | 268.3 | |

| RGG1008 | 103.1 | LR | 8 | 165.03 | 20.63 | 99.8 | RGG2508 | 251.3 | 8 | 402.11 | 50.26 | 301.3 | |

| RGG10010 | 103.1 | LR | 10 | 206.28 | 20.63 | 113.3 | RGG25010 | 251.3 | 10 | 502.64 | 50.26 | 334.2 | |

| RGG10012 | 103.1 | LR | 12 | 247.54 | 20.63 | 126.8 | RGG25012 | 251.3 | 12 | 603.17 | 50.26 | 367.2 | |

| RGG10013 | 103.1 | LR | 13 | 268.17 | 20.63 | 133.6 | RGG25013 | 251.3 | 13 | 653.43 | 50.26 | 383.6 | |

| RGG10014 | 103.1 | LR | 14 | 288.8 | 20.63 | 140.3 | RGG25014 | 251.3 | 14 | 703.7 | 50.26 | 400.1 | |

| RGG1502 | 153.4 | LR | 2 | 61.36 | 30.68 | 91.3 | RGG3002 | 318.1 | 2 | 127.23 | 63.62 | 266.5 | |

| RGG1504 | 153.4 | LR | 4 | 122.71 | 30.68 | 109.6 | RGG3004 | 318.1 | 4 | 254.46 | 63.62 | 307.1 | |

| RGG1506 | 153.4 | LR | 6 | 184.07 | 30.68 | 128 | RGG3006 | 318.1 | 6 | 381.69 | 63.62 | 347.7 | |

| RGG1508 | 153.4 | LR | 8 | 245.43 | 30.68 | 146.4 | RGG3008 | 318.1 | 8 | 508.92 | 63.62 | 388.3 | |

| RGG15010 | 153.4 | LR | 10 | 306.79 | 30.68 | 164.7 | RGG30010 | 318.1 | 10 | 636.15 | 63.62 | 428.9 | |

| RGG15012 | 153.4 | LR | 12 | 368.14 | 30.68 | 183.1 | RGG30012 | 318.1 | 12 | 763.38 | 63.62 | 469.5 | |

| RGG15013 | 153.4 | LR | 13 | 398.82 | 30.68 | 192.3 | RGG30013 | 318.1 | 13 | 827 | 63.62 | 489.9 | |

| RGG15014 | 153.4 | LR | 14 | 429.5 | 30.68 | 201.4 | RGG30014 | 318.1 | 14 | 890.62 | 63.62 | 510.2 | |

| RGG2002 | 206.4 | LR | 2 | 82.56 | 41.28 | 136.1 | RGG4002 | 433 | 2 | 173.21 | 86.6 | 413.7 | |

| RGG2004 | 206.4 | LR | 4 | 165.13 | 41.28 | 161 | RGG4004 | 433 | 4 | 346.42 | 86.6 | 468.4 | |

| RGG2006 | 206.4 | LR | 6 | 247.69 | 41.28 | 185.9 | RGG4006 | 433 | 6 | 519.62 | 86.6 | 523.1 | |

| RGG2008 | 206.4 | LR | 8 | 330.25 | 41.28 | 210.9 | RGG4008 | 433 | 8 | 692.83 | 86.6 | 577.8 | |

| RGG20010 | 206.4 | LR | 10 | 412.81 | 41.28 | 235.8 | RGG40010 | 433 | 10 | 866.04 | 86.6 | 632.6 | |

| RGG20012 | 206.4 | LR | 12 | 495.38 | 41.28 | 260.7 | RGG40012 | 433 | 12 | 1039.25 | 86.6 | 687.3 | |

| RGG20013 | 206.4 | LR | 13 | 536.66 | 41.28 | 273.2 | RGG40013 | 433 | 13 | 1125.85 | 86.6 | 714.6 | |

| RGG20014 | 206.4 | LR | 14 | 577.94 | 41.28 | 285.6 | RGG40014 | 433 | 14 | 1212.46 | 86.6 | 742 | |

| RGG2502 | 251.3 | LR | 2 | 100.53 | 50.26 | 202.4 | RGG5002 | 519.3 | 2 | 207.73 | 103.87 | 512.7 | |

| RGG2504 | 251.3 | LR | 4 | 201.06 | 50.26 | 235.4 | RGG5004 | 519.3 | 4 | 415.46 | 103.87 | 579.2 | |

| RGG2506 | 251.3 | LR | 6 | 301.58 | 50.26 | 268.3 | RGG5006 | 519.3 | 6 | 623.2 | 103.87 | 645.7 | |

| RGG2508 | 251.3 | LR | 8 | 402.11 | 50.26 | 301.3 | RGG5008 | 519.3 | 8 | 830.93 | 103.87 | 712.2 | |

| RGG25010 | 251.3 | LR | 10 | 502.64 | 50.26 | 334.2 | RGG50010 | 519.3 | 10 | 1038.66 | 103.87 | 778.7 | |

| RGG25012 | 251.3 | LR | 12 | 603.17 | 50.26 | 367.2 | RGG50012 | 519.3 | 12 | 1246.39 | 103.87 | 845.1 | |

| RGG25013 | 251.3 | LR | 13 | 653.43 | 50.26 | 383.6 | RGG50013 | 519.3 | 13 | 1350.26 | 103.87 | 878.4 | |

| RGG25014 | 251.3 | LR | 14 | 703.7 | 50.26 | 400.1 | RGG50014 | 519.3 | 14 | 1454.12 | 103.87 | 911.6 | |

| RGG3002 | 318.1 | LR | 2 | 127.23 | 63.62 | 266.5 | RGG6002 | 613.6 | 2 | 245.43 | 122.71 | 609.3 | |

| RGG3004 | 318.1 | LR | 4 | 254.46 | 63.62 | 307.1 | RGG6004 | 613.6 | 4 | 490.86 | 122.71 | 689.7 | |

| RGG3006 | 318.1 | LR | 6 | 381.69 | 63.62 | 347.7 | RGG6006 | 613.6 | 6 | 736.29 | 122.71 | 770.2 | |

| RGG3008 | 318.1 | LR | 8 | 508.92 | 63.62 | 388.3 | RGG6008 | 613.6 | 8 | 981.72 | 122.71 | 850.7 | |

| RGG30010 | 318.1 | LR | 10 | 636.15 | 63.62 | 428.9 | RGG60010 | 613.6 | 10 | 1227.15 | 122.71 | 931.2 | |

| RGG30012 | 318.1 | LR | 12 | 763.38 | 63.62 | 469.5 | RGG60012 | 613.6 | 12 | 1472.58 | 122.71 | 1011.7 | |

| RGG30013 | 318.1 | LR | 13 | 827 | 63.62 | 489.9 | RGG60013 | 613.6 | 13 | 1595.29 | 122.71 | 1051.9 | |

| RGG30014 | 318.1 | LR | 14 | 890.62 | 63.62 | 510.2 | RGG60014 | 613.6 | 14 | 1718.01 | 122.71 | 1092.2 | |

| RGG4002 | 433 | LR | 2 | 173.21 | 86.6 | 413.7 | R Load Return Series | ||||||

| RGG4004 | 433 | LR | 4 | 346.42 | 86.6 | 468.4 | R552C | 55.2 | 2 | 22.1 | 11.04 | 27 | |

| RGG4006 | 433 | LR | 6 | 519.62 | 86.6 | 523.1 | R556C | 55.2 | 6 | 66.3 | 11.04 | 50 | |

| RGG4008 | 433 | LR | 8 | 692.83 | 86.6 | 577.8 | R5510C | 55.2 | 10 | 110.4 | 11.04 | 72 | |

| RGG40010 | 433 | LR | 10 | 866.04 | 86.6 | 632.6 | R1002C | 103.2 | 2 | 41.3 | 20.63 | 52 | |

| RGG40012 | 433 | LR | 12 | 1039.25 | 86.6 | 687.3 | R1006C | 103.2 | 6 | 123.8 | 20.63 | 89 | |

| RGG40013 | 433 | LR | 13 | 1125.85 | 86.6 | 714.6 | R1502C | 153.4 | 2 | 61.4 | 30.68 | 92 | |

| RGG40014 | 433 | LR | 14 | 1212.46 | 86.6 | 742 | R1506C | 153.4 | 6 | 184.1 | 30.68 | 151 | |

| RGG5002 | 519.3 | LR | 2 | 207.73 | 103.87 | 512.7 | R15010C | 153.4 | 10 | 306.8 | 30.68 | 210 | |

| RGG5004 | 519.3 | LR | 4 | 415.46 | 103.87 | 579.2 | R2002C | 206.4 | 2 | 82.6 | 41.28 | 145 | |

| RGG5006 | 519.3 | LR | 6 | 623.2 | 103.87 | 645.7 | R2006C | 206.4 | 6 | 247.7 | 41.28 | 221 | |

| RGG5008 | 519.3 | LR | 8 | 830.93 | 103.87 | 712.2 | R2802C | 283.7 | 2 | 113.5 | 56.74 | 201 | |

| RGG50010 | 519.3 | LR | 10 | 1038.66 | 103.87 | 778.7 | R2806C | 283.7 | 6 | 340.4 | 56.74 | 300 | |

| RGG50012 | 519.3 | LR | 12 | 1246.39 | 103.87 | 845.1 | R3552C | 354.4 | 2 | 141.8 | 70.88 | 302 | |

| RGG50013 | 519.3 | LR | 13 | 1350.26 | 103.87 | 878.4 | R3556C | 354.4 | 6 | 425.3 | 70.88 | 434 | |

| RGG50014 | 519.3 | LR | 14 | 1454.12 | 103.87 | 911.6 | R35510C | 354.4 | 10 | 708.8 | 70.88 | 565 | |

| RGG6002 | 613.6 | LR | 2 | 245.43 | 122.71 | 609.3 | R4302C | 433 | 2 | 173.2 | 86.59 | 440 | |

| RGG6004 | 613.6 | LR | 4 | 490.86 | 122.71 | 689.7 | R4306C | 433 | 6 | 519.5 | 86.59 | 609 | |

| RGG6006 | 613.6 | LR | 6 | 736.29 | 122.71 | 770.2 | R5652C | 565.5 | 2 | 226.2 | 113.1 | 638 | |

| RGG6008 | 613.6 | LR | 8 | 981.72 | 122.71 | 850.7 | R5656C | 565.5 | 6 | 678.6 | 113.1 | 858 | |

| RGG60010 | 613.6 | LR | 10 | 1227.15 | 122.71 | 931.2 | R56510C | 565.5 | 10 | 1131 | 113.1 | 1078 | |

| RGG60012 | 613.6 | LR | 12 | 1472.58 | 122.71 | 1011.7 | ZCC Series | ||||||

| RGG60013 | 613.6 | LR | 13 | 1595.29 | 122.71 | 1051.9 | ZCC500-2 | 550 | 2 | 222.9 | 113.24 | 926 | |

| RGG60014 | 613.6 | LR | 14 | 1718.01 | 122.71 | 1092.2 | ZCC500-4 | 550 | 4 | 445.8 | 113.24 | 1014 | |

| ZDD Very High Tonnage Series | ZCC500-6 | 550 | 6 | 668.8 | 113.24 | 1100 | |||||||

| ZDD500-2 | 550 | LR | 2 | 222.9 | 113.24 | 926 | ZCC500-8 | 550 | 8 | 891.7 | 113.24 | 1188 | |

| ZDD500-4 | 550 | LR | 4 | 445.8 | 113.24 | 1014 | ZCC500-10 | 550 | 10 | 1114.6 | 113.24 | 1274 | |

| ZDD500-6 | 550 | LR | 6 | 668.8 | 113.24 | 1100 | ZCC500-12 | 550 | 12 | 1337.6 | 113.24 | 1362 | |

| ZDD500-8 | 550 | LR | 8 | 891.7 | 113.24 | 1188 | ZCC600-2 | 660 | 2 | 261 | 132.57 | 1100 | |

| ZDD500-10 | 550 | LR | 10 | 1114.6 | 113.24 | 1274 | ZCC600-4 | 660 | 4 | 521.9 | 132.57 | 1199 | |

| ZDD500-12 | 550 | LR | 12 | 1337.6 | 113.24 | 1362 | ZCC600-6 | 660 | 6 | 782.9 | 132.57 | 1300 | |

| ZDD600-2 | 660 | LR | 2 | 261 | 132.57 | 1100 | ZCC600-8 | 660 | 8 | 1043.9 | 132.57 | 1400 | |

| ZDD600-4 | 660 | LR | 4 | 521.9 | 132.57 | 1199 | ZCC600-10 | 660 | 10 | 1304.9 | 132.57 | 1501 | |

| ZDD600-6 | 660 | LR | 6 | 782.9 | 132.57 | 1301 | ZCC600-12 | 660 | 12 | 1565.8 | 132.57 | 1600 | |

| ZDD600-8 | 660 | LR | 8 | 1043.9 | 132.57 | 1400 | ZCC800-2 | 880 | 2 | 358.9 | 182.33 | 1711 | |

| ZDD600-10 | 660 | LR | 10 | 1304.9 | 132.57 | 1501 | ZCC800-4 | 880 | 4 | 717.8 | 182.33 | 1850 | |

| ZDD600-12 | 660 | LR | 12 | 1.565.8 | 132.57 | 1601 | ZCC800-6 | 880 | 6 | 1076.7 | 182.33 | 1991 | |

| ZDD800-2 | 880 | LR | 2 | 358.9 | 182.33 | 1711 | ZCC800-8 | 880 | 8 | 1435.6 | 182.33 | 2116 | |

| ZDD800-4 | 880 | LR | 4 | 717.8 | 182.33 | 1850 | ZCC800-10 | 880 | 10 | 1794.5 | 182.33 | 2280 | |

| ZDD800-6 | 880 | LR | 6 | 1076.7 | 182.33 | 1991 | ZCC800-12 | 880 | 12 | 2153.5 | 182.33 | 2410 | |

| ZDD800-8 | 880 | LR | 8 | 1435.6 | 182.33 | 2116 | ZCC1000-2 | 1100 | 2 | 447.2 | 227.18 | 2452 | |

| ZDD800-10 | 880 | LR | 10 | 1794.5 | 182.33 | 2280 | ZCC1000-4 | 1100 | 4 | 894.4 | 227.18 | 2617 | |

| ZDD800-12 | 880 | LR | 12 | 2153.5 | 182.33 | 2410 | ZCC1000-6 | 1100 | 6 | 1341.7 | 227.18 | 2784 | |

| ZDD1000-2 | 1100 | LR | 2 | 447.2 | 227.18 | 2452 | ZCC1000-8 | 1100 | 8 | 1788.9 | 227.18 | 2950 | |

| ZDD1000-4 | 1100 | LR | 4 | 894.4 | 227.18 | 2617 | ZCC1000-10 | 1100 | 10 | 2236.2 | 227.18 | 3117 | |

| ZDD1000-6 | 1100 | LR | 6 | 1341.7 | 227.18 | 2784 | ZCC1000-12 | 1100 | 12 | 2683.3 | 227.18 | 3283 | |

| ZDD1000-8 | 1100 | LR | 8 | 1788.9 | 227.18 | 2950 | ZCC1500-6 | 1650 | 6 | 2019.5 | 341.96 | 4508 | |

| ZDD1000-10 | 1100 | LR | 10 | 2236.2 | 227.18 | 3117 | |||||||

| ZDD1000-12 | 1100 | LR | 12 | 2683.3 | 227.18 | 3283 | |||||||

| ZDD1500-6 | 1650 | LR | 6 | 2019.4 | 341.96 | 4508 | |||||||

| R_D Series | |||||||||||||

| R1002D | 103 | LR | 2 | 41.2 | 20.6 | 54 | |||||||

| R1006D | 103 | LR | 6 | 123.6 | 20.6 | 81 | |||||||

| R10010D | 103 | LR | 10 | 206 | 20.6 | 108 | |||||||

| R1502D | 153.4 | LR | 2 | 61.4 | 30.7 | 95 | |||||||

| R1506D | 153.4 | LR | 6 | 184.2 | 30.7 | 136 | |||||||

| R2002D | 206.4 | LR | 2 | 82.6 | 41.3 | 136 | |||||||

| R2006D | 206.4 | LR | 6 | 247.8 | 41.3 | 187 | |||||||

| R20010D | 206.4 | LR | 10 | 413 | 41.3 | 239 | |||||||

| R2802D | 283.7 | LR | 2 | 113.4 | 56.7 | 219 | |||||||

| R2806D | 283.7 | LR | 6 | 340.2 | 56.7 | 297 | |||||||

| R28010D | 283.7 | LR | 10 | 567 | 56.7 | 376 | |||||||

| R3552D | 354.4 | LR | 2 | 141.8 | 70.9 | 324 | |||||||

| R3556D | 354.4 | LR | 6 | 425.4 | 70.9 | 421 | |||||||

| R4302D | 433 | LR | 2 | 173.2 | 86.6 | 439 | |||||||

| R4306D | 433 | LR | 6 | 519.6 | 86.6 | 558 | |||||||

| R43010D | 433 | LR | 10 | 866 | 86.6 | 673 | |||||||

| R5652D | 565.5 | LR | 2 | 226.2 | 113.1 | 619 | |||||||

| R5656D | 565.5 | LR | 6 | 678.6 | 113.1 | 772 | |||||||

| R56510D | 565.5 | LR | 10 | 1131 | 113.1 | 926 | |||||||

The TWHC series square drive torque wrench is designed for high cycle quality and lower cost of ownership. Intently constructed for a cycle life two to three times longer than existing technology.

The TWLC series wrench is a lightweight, low profile tool featuring low height and a tight nose radius. The TWLC series wrench was designed for the most inaccessible bolting areas found in industry.

– Increased reliability: simple drive assembly means less downtime

– Corrosion resistant material used for use in harsh environments

– Compact nose radius

– Working Pressure of 10,000 PSI

– Multi-direction high flow swivel manifold

– Swivel manifold internal relief valve prevents retract side over-pressurization

– Fine tooth pawl effectively prevents tool “lock-on”

– TWLC Powerthon™️️️️️️️️️️️️️️️️️️ Lifetime Warranty

| Model | Min Torque | Max Torque | Drive | Weight (lbs) |

| Square Drive Standard Rear Reaction | ||||

| TWHC1 | 170 | 1413 | ¾” | 6.2 |

| TWHC3 | 376 | 3136 | 1” | 11.7 |

| TWHC6 | 726 | 6050 | 1.1/2” | 19.4 |

| TWSD11 | 1313 | 10940 | 1.1/2” | 28.9 |

| TWSD25 | 3984 | 24500 | 2.1/2” | 65 |

| TWHC50 | 6360 | 53000 | 2.1/2” | 152 |

| Model | Min Torque | Max Torque | Standard Link Sizes | Weight (lbs) |

| Low Profile | ||||

| TWLC2 | 189 | 1575 | 1 – 2.3/8” | 2.2 |

| TWLC4 | 477 | 3975 | 1.5/16 – 3.1/8” | 4.4 |

| TWLC8 | 954 | 7950 | 1.7/8 – 3.15/16” | 7.7 |

| TWLC15 | 1782 | 14850 | 2.7/16 – 4.5/8” | 15.4 |

| TWLC30 | 3456 | 28800 | 3.1/8 – 6.1/16” | 31.9 |

SRT Spring Return design dramatically increases productivity and safety on the job site when compared to older technology manual return tensioners.

MRT manual return economy range of bolt tensioners offer low-cost tensioning solutions. Incorporating our unique quick-release bridge adaptation, a range of adapter kits provide maximum flexibility.

Our tensioners have quality designed in with standard features that enhance durability and efficiency to get the job done faster and safer

WSS and WSL wind tensioners compatible with ISO Metric threaded and all-thread bars

– Piston overstroke prevention

– Corrosion resistant material used for use in harsh environments

– SRT and MRT are inter-compatible

– Working Pressures of 19,850 – 21,750 PSI

– Electric, Pneumatic, and Manual Pumps Available

– SRT and MRT Designed to fit BS1560/ANSI B16.5/API flanges

– WDD and WSD Achieve 90% proof load requirement for ISO 898 Grade 10.9 bolts

– WDD and WSD Self-energizing, long life seals

– Wind tensioners have tool lifting-strap as standard

– Wind tensioners available with Geared or Manual Nut Rotator

– Hydraulic Nut Leave-On Tensioners Available on Bolting and Tensioning Catalog Page 57

| Model | Bolt Diameter | Pressure PSI | Kips | Imperial and Metric? |

| Standard Tensioners | ||||

| SRT Spring Return Series | ¾” to 4.1/2” | 21750 | 36 to 921 | Yes |

| MRT Manual Return Series | 1” to 4” | 21750 | 63 to 719 | Yes |

| Wind Tensioners | ||||

| WDD Up Tower Series | M30 to M42 | 19580 | 105 to 208 | Metric |

| WSD Compact Tower Series | M30 to M42 | 19580 | 105 to 208 | Metric |

| WSS and WSL Foundation Wind Series | #10 – 11 | 1.1/4” to 1.3/8” | 19580 | 106 to 171 | ISO Metric threaded and all-thread bars |

| More info and accessories on Tensioning Catalog Page 35 |

– PT Power Team Posi-Lock®️️️️️️️ pullers make pulling bearings a one-person operation. The T-handle and “Safety Cage®️️️️️️️” control the jaws at all times

– Hydraulic pullers come with a lift plate for ease of transport and lifting. In addition, ram points of different sizes are available for a variety of applications

– PTPH Pullers up to 200 TONS

– ENS Nut-Splitters feature a triple edge replaceable cutting blade

– ENS Size range from M20 to M90 (3/4″ to 3-1/2″) bolt diameters

– Nut-splitters available in single or double acting

– Subsea Nut-Splitters available in the ENS series

– Built-in safety relief valve to protect tool & operator

– Products use a standard 10,000 PSI pump

– Double acting (subsea) version comes standard with 700 bar, 1/4″ NPT, Push to Connect (PTC) couplers. To use with top side pumps, change out couplers to 700 bar, 1/4″ NPT, Screw-to-connect style

| Hydraulic Nut-Splitters | Single or Double Acting? | Hydraulic POSI-LOCK Pullers | |||||||||||||

| Model | 2 or A Nut Hex in. | 5 or B Nut Hex in. | 8 or C Nut Hex in. | 2H Nut Hex in. | Model | Tons | Jaw Qty | Bolt Dia. In. (mm) | Reach In. (mm) | Spread In. (mm) | Weight lbs (kg) | ||||

| HNS150 | 1/2 – 1-1/2 | 1/2 – 1- 1/2 | 1/2 – 1-5/16 | 1/2 – 1-1/8 | Single | PT202 | 1 | 2 | 0.31 (7.9) | 2.25 (57) | 3.25 (82.6) | 0.62 (0.28) | |||

| HNS150A | 1/2 – 1-1/2 | 1/2 – 1-1/2 | 1/2 – 1-5/16 | 1/2 – 1-1/8 | Single | PT203 | 2 | 2 | 0.37 (9.4) | 3.00 (76.2) | 4.50 (127) | 1.12 (0.51) | |||

| HNS225 | 1-1/8 – 2-1/4 | 1-1/8 – 2-1/4 | 1-1/8 – 2-1/4 | 1-1/8 – 1-11/16 | Single | PT204 | 2 | 2 | 0.5 (12.7) | 4.00 (102) | 5.00 (127) | 3 (1.36) | |||

| ENS Nut-Splitter (Subsea Available) | PT206 | 6 | 2 | 0.62 (15.8) | 6.00 (152) | 7.00 (178) | 7 (3.18) | ||||||||

| Cylinder Model | Nut Capacity | Bolt Diameter | Weight | Single or Double Acting | PT208 | 12 | 2 | 0.75 (19 ) | 8.00 (203) | 12.00 (305) | 12 (5.44) | ||||

| ENSAS010001 | 1.1/4” – 2” | ¾” – 1.1/4” | 15.2 | Single | PT210 | 14 | 2 | 0.75 (19) | 9.67 (246) | 15.00 (381) | 13 (5.9) | ||||

| ENSAS010004 | 1.1/4” – 2” | ¾” – 1.1/4” | 15.2 | Double | PT213 | 25 | 2 | 1.12 (28.5) | 12.00 (305) | 18.00 (457) | 38 (17.24) | ||||

| ENSAS020001 | 1.13/16” – 2.3/4” | 1.1/8” – 1.3/4” | 35.3 | Single | PT216 | 35 | 2 | 1.25 (32) | 14.00 (356) | 25.00 (635) | 57 (25.85) | ||||

| ENSAS020004 | 1.13/16” – 2.3/4” | 1.1/8” – 1.3/4” | 35.3 | Double | PT102 | 1 | 3 | 0.31 (7.9) | 2.25 (57) | 3.25 (82.6) | 0.68 (0.31) | ||||

| ENSAS030001 | 2.3/4” – 4.1/4” | 1.3/4” – 2.3/4” | 97 | Single | PT103 | 2 | 3 | 0.37 (9.4 ) | 3.00 (76.2) | 4.50 (114.3) | 1.3 (0.59) | ||||

| ENSAS030006 | 2.3/4” – 4.1/4” | 1.3/4” – 2.3/4” | 97 | Double | PT104 | 5 | 3 | 0.5 (12.7) | 4.00 (102) | 5.00 (127) | 4.1 (1.86) | ||||

| ENSAS040001 | 4.1/4” – 5.3/8” | 2.3/4” – 3.1/2” | 165 | Single | PT106 | 10 | 3 | 0.62 (15.8) | 6.00 (152) | 7.00 (178) | 8 (3.63) | ||||

| ENSAS040004 | 4.1/4” – 5.3/8” | 2.3/4” – 3.1/2” | 165 | Double | PT108 | 17 | 3 | 0.75 (19) | 8.00 (203) | 12.00 (305) | 14 (6.35) | ||||

| PT110 | 20 | 3 | 0.75 (19) | 9.67 (246) | 15.00 (381) | 16 (7.26) | |||||||||

| PT113 | 30 | 3 | 1.12 (28.5) | 12.00 (305) | 18.00 (457) | 44 (19.96) | |||||||||

| PT116 | 40 | 3 | 1.25 (32) | 14.00 (356) | 25.00 (635) | 68 (30.84) | |||||||||

| PTPH High Tonnage Pullers | |||||||||||||||

| Model | Cap. TONS | Jaws | Reach (in.) | Spread (in.) | Tip Width (in.) | Tip Clearance (in.) | Depth (in.) | Weight (lbs) | |||||||

| PTPH-102T | 100 | 2 | 50 | 70 | 125 | 3.5 | 3.5 | 1700 | |||||||

| PTPH-100T | 100 | 3 | 50 | 70 | 125 | 3.5 | 3.5 | 1950 | |||||||

| PTPH-123T | 100 | 2 or 3 | 50 | 70 | 125 | 3.5 | 3.5 | 2000 | |||||||

| PTPH-102TV Vertical | 100 | 2 | 50 | 70 | 125 | 3.5 | 3.5 | 1800 | |||||||

| PTPH-102TDA | 100 | 2 | 50 | 70 | 125 | 3.5 | 3.5 | 1800 | |||||||

| PTPH-100TDA | 100 | 3 | 50 | 70 | 125 | 3.5 | 3.5 | 2050 | |||||||

| PTPH-123TDA | 100 | 2 or 3 | 50 | 70 | 125 | 3.5 | 3.5 | 2100 | |||||||

| PTPH-102DATV Vertical | 100 | 2 | 50 | 70 | 125 | 3.5 | 3.5 | 1800 | |||||||

| PTPH-200T | 200 | 4 | 48 | 70 | 125 | 3.5 | 3.5 | 4150 |

SPX Power Team carries a very large selection of tools – more than we have listed here, including but not limited to:

– Product Dimensions

– Spreaders

– Manual Pullers

– Hydraulic Nuts

– Inflatable Jacks

– Toe Jacks

– Bottle Jacks

– Gauges, Hoses, Fittings, Manifolds, and Other Accessories

– Press Units

– Reaction Arms

and More! Check out the below catalog PDFs or call for more:

Call Now

SPX Catalog PDF

SPX Bolting and Tensioning Catalog PDF

SPX Power Team carries a very large selection of tools – more than we have listed here, including but not limited to:

– Product Dimensions

– Spreaders

– Manual Pullers

– Hydraulic Nuts

– Inflatable Jacks

– Toe Jacks

– Bottle Jacks

– Gauges, Hoses, Fittings, Manifolds, and Other Accessories

– Press Units

– Reaction Arms

and More! Check out the below catalog PDFs or call for more:

Call Now

SPX Catalog PDF

SPX Bolting and Tensioning Catalog PDF

Click here to call and check availability and set it up!!

Call NowClick here to call and check availability and set it up!!

Call Now